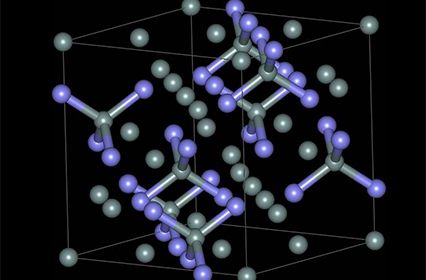

1.the heat resistance can reach 1300-1400℃, and this material has good oxidation resistance. This kind of ceramics has a small friction coefficient and strong adhesive ability, which is suitable for processing the material of casting silicon aluminum alloy and other materials that prone to form chips.

2.They contain hard dispersed second phase heat-resistant carbide or nitride and possess high hardness, strength, fracture toughness, and smaller thermal expansion coefficient. these cutting tools are especially suitable for the rough and finishing processing, high-speed cutting, and heavy cutting of cast iron and high-temperature alloy. The cutting durability is several times higher than that of the cemented carbide tool.

WE Will Meet you at AHR 2025 in ORLANDO

WE Will Meet you at AHR 2025 in ORLANDO

Silicon Nitride (Si3N4) Applications

Silicon Nitride (Si3N4) Applications